Schwarze-Robitec designs system with Rotary machine: With the individual bending cell to a fully automated manufacturing process

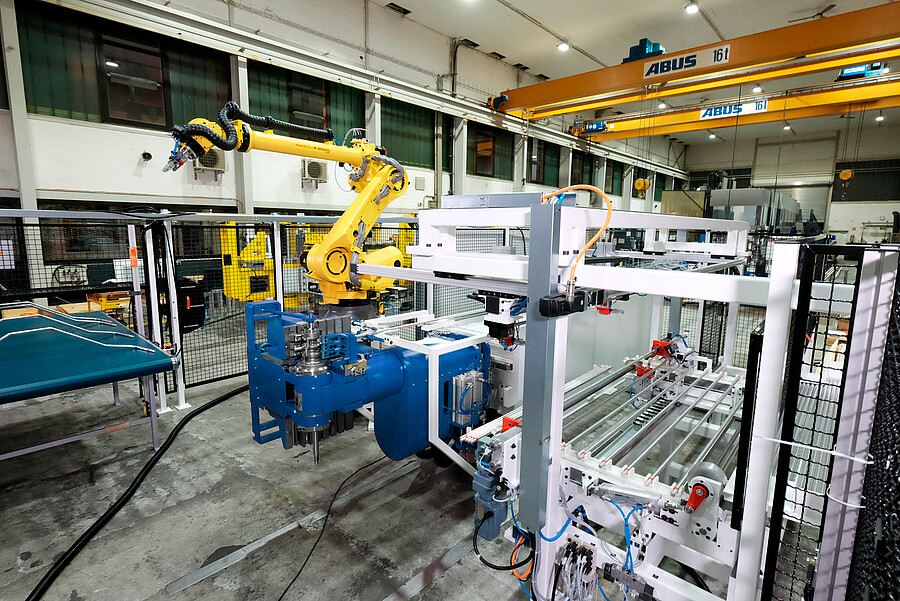

Fully automatic, efficient, process-reliable – bending cells show their advantages especially in large-scale production. They reduce cycle times and perform bending tasks with maximum precision. The CNC 40 Rotary from Schwarze-Robitec’s High Performance series can also be easily expanded into a bending cell. Thanks to its freely rotating bending head, it realizes even complex tube geometries without collisions. All steps related to tube processing – from tube feeding to loading and unloading of the machine to post-processing – are automated. Each bending cell is designed by Schwarze-Robitec to be highly customized to the user’s production requirements.

The CNC 40 Rotary bends tubes made of all common materials such as aluminum, titanium, copper, steel, and stainless steel with a diameter of 0.25 to 1.5 inch. This also applies to tubes with already preformed contours. Thanks to its rotating bending head, the rotary function offers the particular advantage that tubes can be bent in both left and right bending directions in a single operation. For users who want to rely on fully automated production, the CNC 40 Rotary can be upgraded to a bending cell. The advantages of this option, which is open to all CNC bending machines, quickly become clear.

Fully automated for a constant, plannable production chain

Bending cells with CNC-controlled tube bending machines are mainly used in automotive production, increasingly also for the production of electric cars. They are also used in industries such as refrigeration and air conditioning. In this way, different tube systems are produced, such as exhaust pipes, injection and cooling water lines, or even current-carrying conductor rods with complex tube geometries. In order to produce such elements, often with extremely small bending radii, users must manufacture in short cycle times and yet with high precision. A fully automated bending cell gives them the advantage of a particularly constant and plannable production chain. This is because Schwarze-Robitec combines all work steps before and after bending according to customer-specific requirements into an efficient overall process.

Individual requirements determine the choice of systems

Depending on the area of application, the tube feed in the bending cells can be carried out via different systems, for example belt conveyors, bunker or chain conveyors. With regard to the loading of the tube bending machine, Schwarze-Robitec also offers its own systems such as swivel and gantry loaders. On the other hand, the tube bending specialist also enables the integration of robots from a wide range of manufacturers. Furthermore, the loading can be supplemented by a wide range of additional functions, for example by systems for tube separation and sorting or for weld seam detection. The individual requirements of the user determine which loading handling system is optimally suited to the production process. The bending process is followed by tube unloading and, if required, further tube processing. Here, too, Schwarze-Robitec can implement the different variants of unloading handling in a part-specific manner – for example, the tube is transferred from the machine with the robot to the conveyor belt or via a chute into the customer-specific container. Throughout the entire process, an overall cell control system ensures a constant and uninterrupted bending process.

With experience and intensive consulting to the optimal bending cell

Every bending cell is designed by Schwarze-Robitec specifically for the customer’s needs and with the selection of exactly fitting systems. Intensive consultation and coordination throughout the project lead to the optimal design of the system. “When implementing a bending cell, we act as a general contractor,” says Bert Zorn, managing director of Schwarze-Robitec. “The customer receives everything from a single source, from the idea to the finished bending cell in operation. The linchpin at all times is the very individual specifications and features of his production process: we align the entire system layout to them and design a unique, customer-specific system.” To this end, Schwarze-Robitec relies on decades of experience and profound expertise in tube bending – and at the same time is ideally equipped for future tasks: While individual tube systems are currently still mainly produced in large quantities, the trend is moving towards automation of bending processes for small batches – combined with significantly more complex processes and sophisticated software solutions. The tube bending machines from Schwarze-Robitec are therefore optimally designed both mechanically and in terms of software for integration into bending cells and for customer-specific adaptation.