Peak Performance in Tube Bending Technology

The machinery manufacturer Schwarze-Robitec is showcasing three CNC tube bending machines tailored to meet the highest standards in large-scale and series production at this year’s Tube in Düsseldorf. On stand E 31 in hall 5, the long-established Cologne-based company will be exhibiting a CNC 40 Rotary, a CNC 80 E TB MR with Circular Cutting Device exhibited as a fully automatic bending cell and a CNC E 25 Orbital.

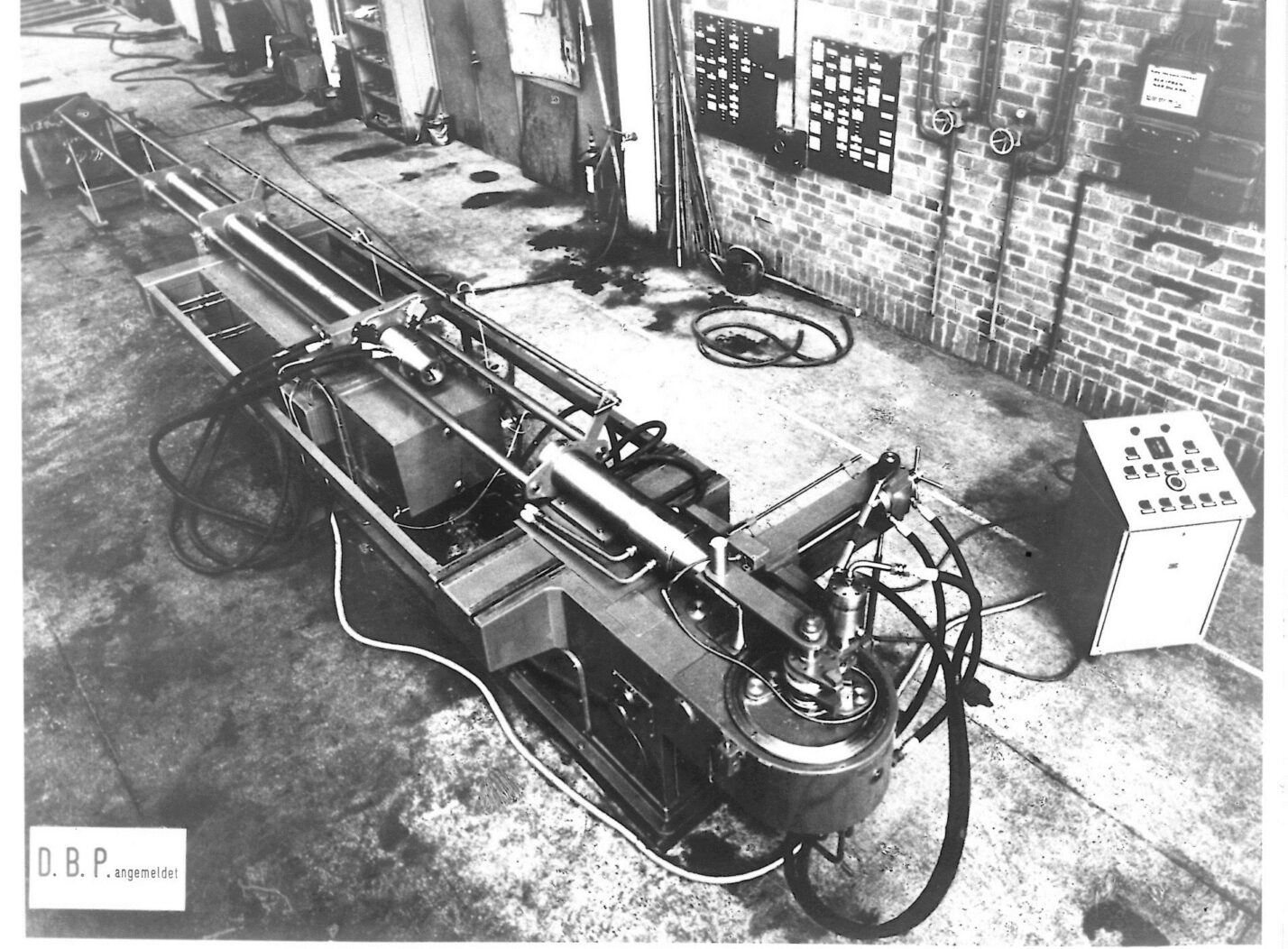

Schwarze-Robitec will once again be present at Tube, the world’s leading trade fair for the tube industry. With three high-quality tube bending machines from the High Performance series, the company will provide information on intelligent and innovative tube bending solutions. One of the three machines is the CNC 40 Rotary. The tube bending machine has a freely rotating bending head and can therefore bend tubes both to the left and to the right. This is particularly useful for tight bending radii. The Rotary machines are designed for continuous and long-term use in large and series production and are characterised by their flexibility. Tubes with complex geometries are bent in a single operation at maximum speed and in the shortest possible cycle time.

All-electric and highly efficient

With the CNC 80 E TB MR, Schwarze-Robitec presents a fully electric multi-radius tube bending machine that combines the two process steps of bending and cutting, thus enabling short cycle times. The circular cutting device patented by Schwarze-Robitec and implemented in the machine allows tubes to be cut into individual pieces without material waste. Three cutting wheels move around the tube several times at 120° intervals and cut it off gradually. There are no chips and the cut quality is excellent, so no additional calibration is required. At this year’s Tube, the CNC 80 E TB MR will be integrated into a fully automatic bending cell. All production steps related to bending are thus optimally interlinked. With the compact CNC E 25 Orbital, individual busbars and entire systems can be bent into complex geometries. The ingenious machine design allows bending on both the flat and high sides of the busbars. Whether copper or aluminium, with or without insulation, the CNC E 25 Orbital offers maximum speed with maximum precision to meet the demanding requirements of the e-automotive industry.

Schwarze-Robitec’s experts will be available to answer visitors’ questions on current industry trends and the latest developments at stand E 31 in hall 5.