The efficient all-rounder for plant construction, shipbuilding and the offshore industry

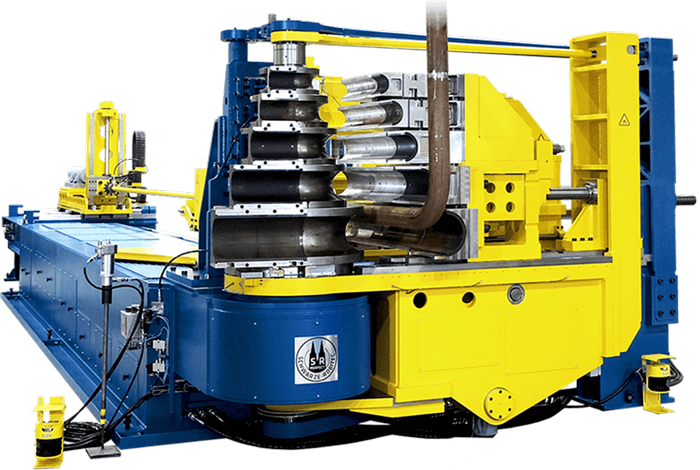

The automatic CNC mandrel bending machines of our HEAVY DUTY range offer you additional flexibility for optimal profitability. The HD machines are designed for continuous use in tough conditions. Their particularly high rigidity prevents the machine body from twisting at high clamping forces which results in high-quality bending results. These machines are also very user-friendly and can be integrated seamlessly into all relevant networks and programs. Our CNC HD bending machines enable you to produce the most complex geometries in one single operation. As a result, you can very quickly manufacture three-dimensional tube systems without a single weld – a major productivity advantage.

A robust basic machine with many options

The core of our HEAVY DUTY range of bending solutions is a very stable and extremely rigid basic machine which is capable of withstanding enormous bending forces. The enormous reserves of the clamping functions ensure excellent bending results.

CNC 60 HD

max. Ø 60mm

CNC 220 HD

max. Ø 219,1mm

CNC 420 HD

max. Ø 419mm

CNC 80 HD

max. Ø 89mm

CNC 265 HD

max. Ø 273mm

CNC 450 HD

max. Ø 457mm

CNC 100 HD

max. Ø 114,3mm

CNC 320 HD

max. Ø 323,9mm

CNC 165 HD

max. Ø 168,3mm

CNC 350 HD

max. Ø 355mm

Tube bending solutions, customised by the expert

For decades, our company has stood for innovation and maximum quality “Made in Germany”.

Our many years of expertise in producing tube bending solutions for plant construction, shipbuilding and the offshore industry enable us to come up with the best solution for your needs. The combination of our first-class tube bending technologies, an extensive range of smart add-on modules and a global service offering provide you with a unique, high-performance and future-proof package.

The benefits at a glance

Our automatic tube cold bending machine is the ideal basis for efficient tube bending solutions for many high-performance industrial applications. If you would like any further information or you need advice about your individual specifications, please contact us without obligation.

-

Especially high performance for thick-walled tubes

-

For tubes with a diameter of up to 450 mm

-

Extensive range of optional extras

-

Suitable for complex tube geometries

-

Bending of double-walled and flanged pipes possible

-

Automation option available

Customised bending solutions: more than the sum of their parts

Individual requirements call for individual solutions – the entire package needs to be right.

Our modular machine and accessory ranges enable us to work with you to tailor the most efficient tube bending solution for your application. From optimal tooling for your machine and smart and user-friendly control systems to high-precision measuring devices and software-based tube bending simulation: there are virtually no limits to the available options. Our many years of experience working with customers in different industries helps us to find the right technology and service solutions for your specific requirements.

HEAVY DUTY – robust tube bending machines for plant construction, shipbuilding and the offshore industry

Our HEAVY DUTY machines are designed for continuous use in tough conditions. Their particularly high rigidity prevents the machine body from twisting at high clamping forces which delivers high-quality bending results even in fast production cycles. Whether you are producing complex geometries or different bending radii, our HEAVY DUTY machines ensure maximum precision at high forces – all in a user-friendly package.

Please feel free to contact us for advice about the right machine for your needs.

The world’s leading expert in tube bending machines

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.