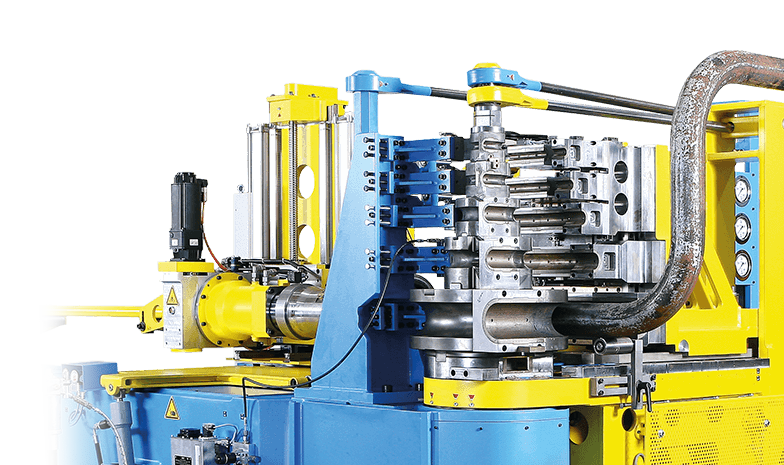

What good is a tube bending machine without the optimal tools?

We design and manufacture the right tools for your tube bending requirements: for series production, complex tube geometries, tube serpentines and thin-walled tubes. Whatever you need, we have the experience and the means to supply the optimal tools for your machine.

The bending tools for Schwarze-Robitec tube bending machines are specially hardened to ensure their wear resistance and dimensional stability which results in a high degree of precision and a high-quality production solution that lasts for many years.

We can supply tools for tube bending machines for use in various applications including:

- Series and large-scale production

- Multi-stack bending tools for plant construction and shipbuilding

- Tools for booster bending machines for use in boiler construction

Our bending tools are unique

Our designers discuss your requirements with you and develop tools that are tailored perfectly to your tube bending machine. Long-term availability is ensured because we can quickly manufacture and deliver spare parts on the basis of the data we have stored.

Your operational security is ensured by our permanent spare parts availability and our rapid in-house manufacture of individual components.

High-performance bending tools

Bending tools for series and large-scale production

Whether you are bending different radii or materials, our machines can be equipped variably with the right tools for your needs.

Automatic, fast, smart

The multi-radius bending tool enables particularly fast production processes. You can conveniently store your product parameters in the system and call them up as needed to ensure precision and reproducibility.

Boiler & Power bending tools

Bending tools for boiler and power plant construction

All the components of our booster bending machine – machine body, bending head, bending tool and drive technology – interact perfectly to ensure rapid, precise and economical production.

Speed is the key

In most cases, our bending heads eliminate the need to additionally support the tie rod. This results in easy tool changing and faster bending processes, even for complex geometries.

Reliable manufacturing processes

Our clamping device ensures that the tubes are perfectly positioned, even in tough conditions. Split bend formers for either vertical or horizontal mounting make your process flexible and facilitate the processing of tubes with a bending angle of more than 180 degrees. We supply solid bend formers for extremely small bending radii of less than 1 x D.

Heavy Duty bending tools

Bending tools for plant construction, shipbuilding and the offshore industry

As an experienced specialist and leading innovator in our industry, we design and produce the bending tools for your needs which determine the optimal tooling for your machine. We use the best specially hardened materials for your tools. These are highly corrosion-resistant and hard-wearing, enabling you to manufacture your products in the highest quality for many years. In addition, the use of flexible multi-level tools gives you the option of significantly reducing refitting times, a key factor in optimising cost-efficiency.

Customised bending solutions: more than the sum of their parts

Individual requirements call for individual solutions – the entire package needs to be right.

Our modular machine and accessory ranges enable us to work with you to tailor the most efficient tube bending solution for your application. From optimal tooling for your machine and smart and user-friendly control systems to high-precision measuring devices and software-based tube bending simulation: there are virtually no limits to the available options. Our many years of experience working with customers in different industries helps us to find the right technology and service solutions for your specific requirements.

The world’s leading expert in tube bending machines

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.