Powerful, robust and durable: our HEAVY DUTY tube bending machines

The name means what it says: HEAVY DUTY, strong bending performance for continuous use in the toughest conditions. All the HD machines are based on extremely robust and powerful basic machines. Thanks to our technical expertise and decades of experience as a leading innovator in the industry, our machines offer you entirely new options in response to growing requirements. They permit the efficient and precise bending of complex tube geometries without a single weld, even when using high-strength materials and very large as well as thick-walled and thin-walled tubes.

From the highly economical and user-friendly solution to machines that can handle 40-metre tubes or entire tube workshops with integrated tube magazine and automatic tube feeder, we always develop the solution which meets your needs precisely. Maximum productivity and availability coupled with forward-looking technology are our guarantees for your success.

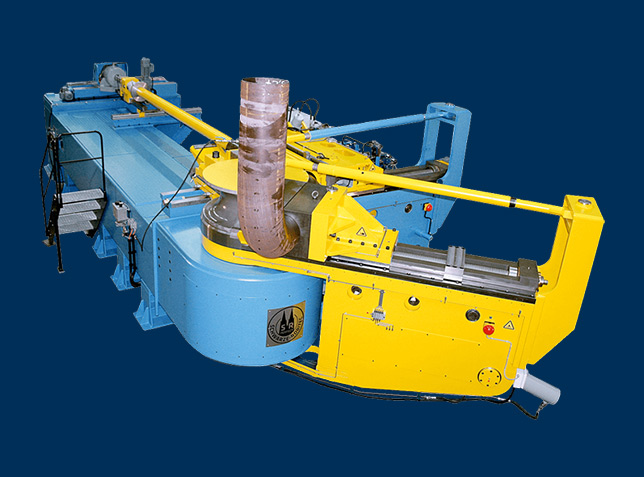

Semi-automatic tube bending machines for series production and single bends

The cost-effective alternative without compromising on quality or performance: Thanks to their special user-friendliness our semi-automatic tube bending machines are the ideal flexible solution for the production of small series or single bends.

Automatic tube bending machines

For fully automated production in the toughest conditions, the CNC mandrel bending machines from our HEAVY DUTY range are the ultimate backbone for pipe bending solutions in plant construction, shipbuilding and the offshore industry. Maximum force and precision are the basis for endless possibilities and sustainable efficiency.

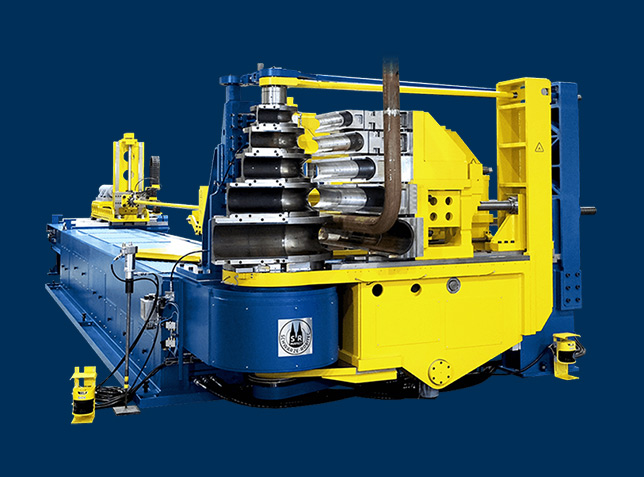

Tube bending machine with multi-stack bending tool

Thanks to the use of multi-stack bending tools, our CNC HD MW machines are true masters of efficiency.

A reduction of up to 70 percent in setup times enables you to cut downtimes to a minimum while leveraging all the advantages of our fully automatic tube bending machines at the same time. This enables you to achieve first-class results and sustainable efficiency, especially if you have high requirements in terms of the flexibility of your solution.

Customised bending solutions: more than the sum of their parts

Individual requirements call for individual solutions – the entire package needs to be right.

Our modular machine and accessory ranges enable us to work with you to tailor the most efficient tube bending solution for your application. From optimal tooling for your machine and smart and user-friendly control systems to high-precision measuring devices and software-based tube bending simulation: there are virtually no limits to the available options. Our many years of experience working with customers in different industries helps us to find the right technology and service solutions for your specific requirements.

The world’s leading expert in tube bending machines

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.