Flexibly configurable bending solutions for electromobility

Schwarze-Robitec supports the transition to sustainable transportation with innovative bending solutions for electric vehicles. Lightweight construction is crucial, as every kilo saved reduces electricity consumption. There is a growing demand for thin-walled tubes made from high-strength materials and lightweight materials such as aluminum and carbon fiber-reinforced plastics. Complex, asymmetrical shapes are replacing traditional round tubes. Power lines made of aluminum profiles and round rods are replacing copper cables. Our bending technology meets all these new requirements.

Our products

We develop customized, configurable special machines that reduce cost pressure and increase production efficiency through efficiency and precision.

Our modern busbar bending machines offer tailored solutions for your production requirements and ensure precision, efficiency and flexibility. We offer bending machines for flat and round material.

-

Optimized bending solution for busbars

-

For complex geometries

-

Fast, efficient and precise

-

Minimal set-up times

-

High bending speed

-

Extensive equipment options

-

Automation optionally possible

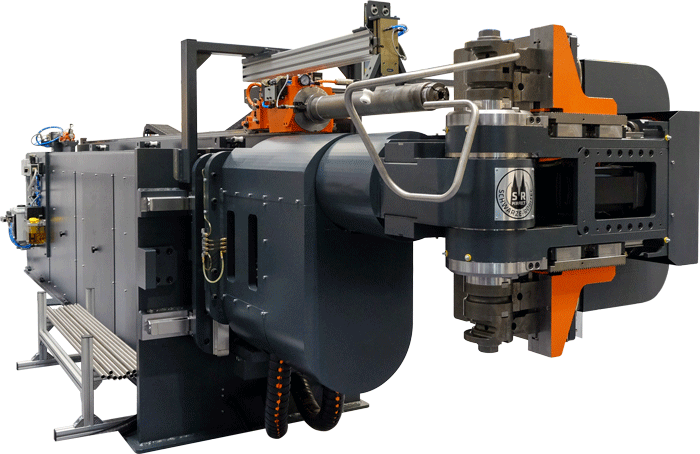

Orbital series

Specially designed for bending busbars made of flat material. Enables left and right bending over the high and flat side in one cycle. Precisely tailored to individual geometries to ensure maximum design flexibility and high precision.

CNC 25 E Orbital: max. Ø 25mm

CNC 40 E Orbital: max. Ø 40mm

High-performance series

For flat and round busbars. Enables left and right bending in one cycle, with different radii or short intermediate lengths.

CNC 25 E TB MR: max. Ø 25mm

CNC 25 Rotary: max. Ø 25mm

CNC 40 E Orbital: max. Ø 40mm

CNC 40 Rotary: max. Ø 40mm

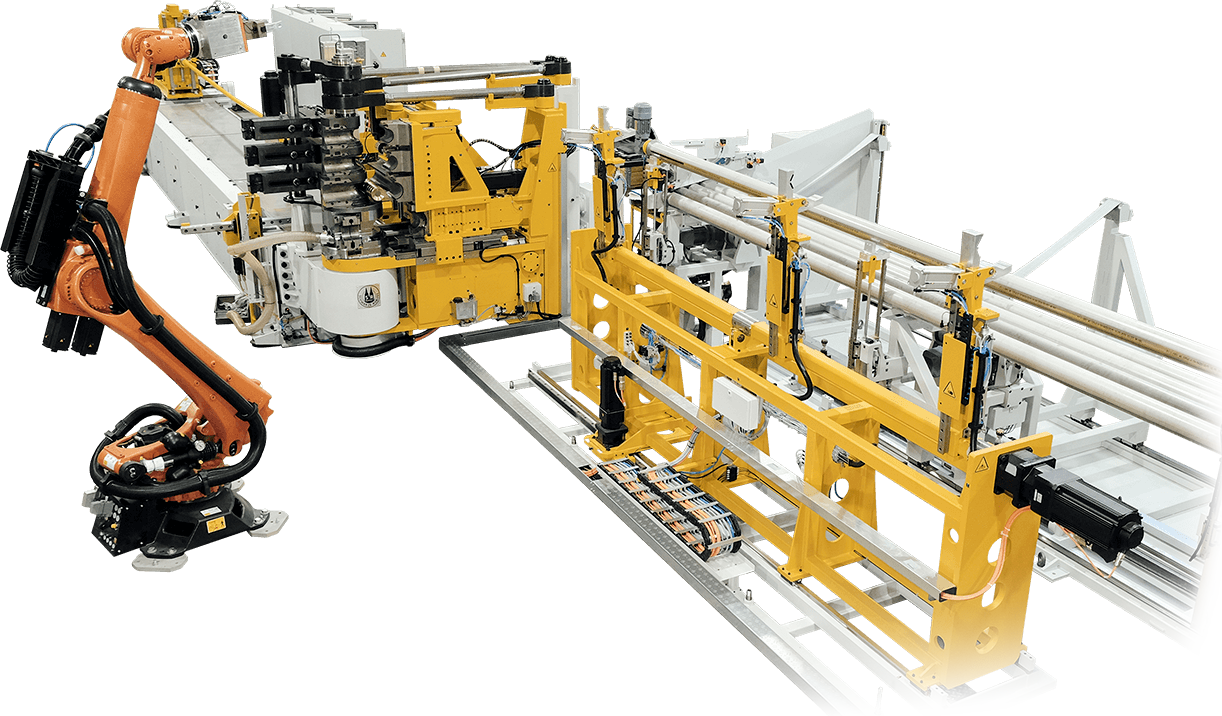

Fully automatic bending cells

For the efficient bending of cut-to-length busbars. Consists of magazine, bending machine and handling system. Can be complemented with upstream or downstream processes such as part identification and production data acquisition.

Fully automatic production lines

For insulated and non-insulated materials. Straightening, cutting and processing steps such as stripping and punching are seamlessly performed before bending. Multiple bending machines can be integrated to minimize material preparation steps.