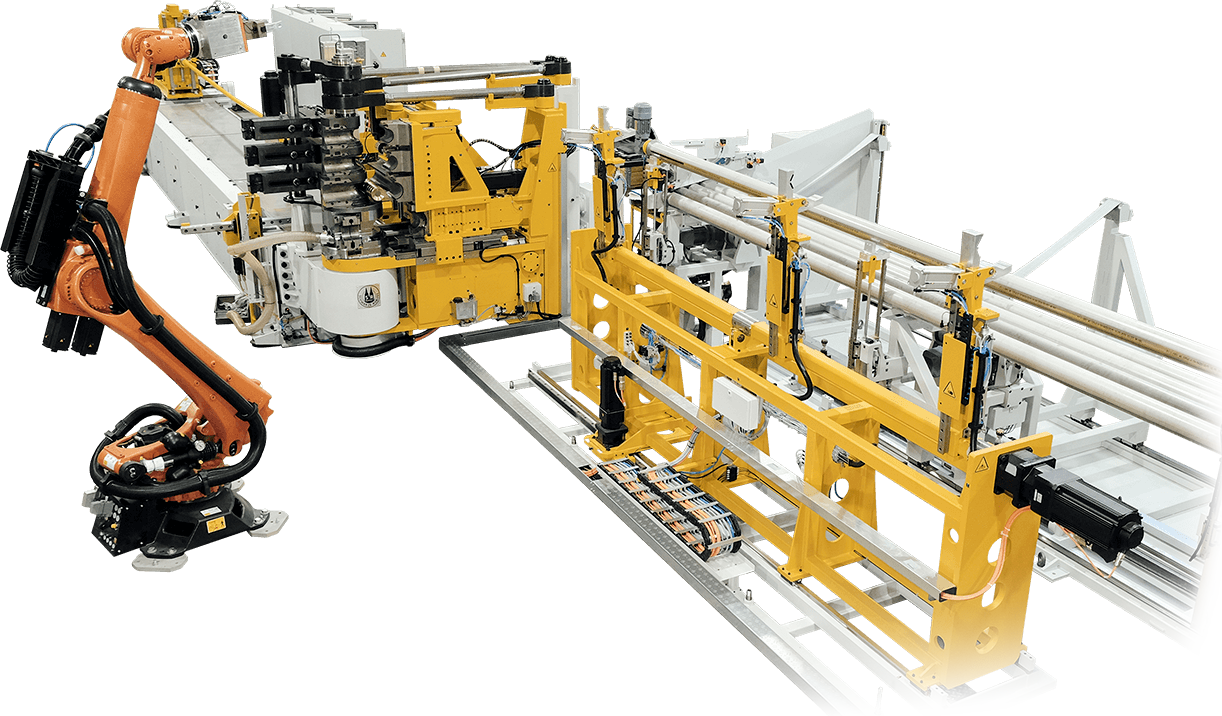

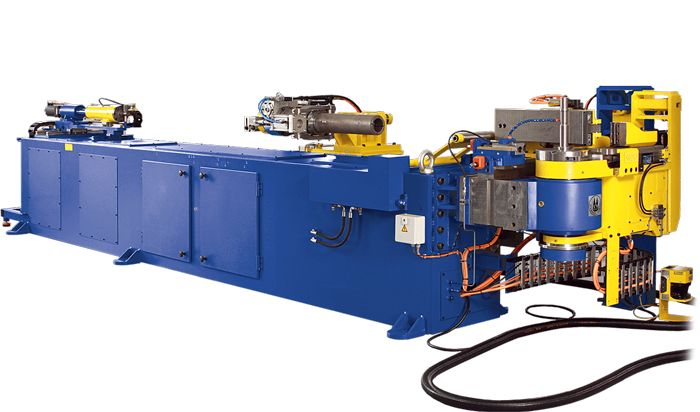

Fully automated, efficient and reliable – our bending cells for series production

Users who want a fully automated production process have the option of expanding any CNC bending machine to create a bending cell. A highly complex, fully automated bending cell gives you the advantage of a very consistent and reliable manufacturing process. On the basis of your individual production requirements, you can choose from a range of systems for tube feeding, insertion, removal and end finishing. An overall cell control system ensures continuous and uninterrupted tube bending throughout the process. It is also possible to integrate robots from other manufacturers. Bending cells with CNC tube bending machines are often used in automotive production, increasingly in the manufacture of electric cars as well.

Benefits in series and large-scale production

Fully automated bending cells deliver benefits in large-scale production especially and are thus a permanent feature of our HIGH PERFORMANCE range. All tube processing operations – tube feeding, insertion, removal and post-processing – are automated. Expanding a machine to create a fully automated bending cell therefore improves the entire production process and makes it more efficient. Users also benefit from maximum precision and short cycle times.

A tradition of quality

For more than 80 years, we have been developing high-quality customised bending solutions for many different applications. We are familiar with the current requirements of our customers’ industries; manufacturing companies are facing the challenge of ensuring their processes are up to date and more cost-effective. For this reason, we are working consistently to develop new tube processing standards for the future.

The benefits at a glance

Each CNC tube bending machine can be expanded to create a fully automated bending cell on the basis of your individual requirements. If you would like any further information or you need advice about your individual specifications, please contact us without obligation.

-

Customer-specific automation concepts

-

Fast, efficient and precise

-

Flexible automation from the first batch

-

Suitable for fully automatic large-scale production

-

Optional integration of various processing and handling options

-

Degree of automation optimised to meet real needs

-

All-in-one solutions: full automation and integration from a single supplier

-

Suitable for three-shift operation

Customised bending solutions: more than the sum of their parts

Individual requirements call for individual solutions – the entire package needs to be right.

Our modular machine and accessory ranges enable us to work with you to tailor the most efficient tube bending solution for your application. From optimal tooling for your machine and smart and user-friendly control systems to high-precision measuring devices and software-based tube bending simulation: there are virtually no limits to the available options. Our many years of experience working with customers in different industries helps us to find the right technology and service solutions for your specific requirements.

HIGH PERFORMANCE – tube bending machines for series and large-scale production

The fully automated bending cells from our HIGH PERFORMANCE range are the perfect answer to the exacting requirements of series and large-scale production. Thanks to their speed, performance and customisation to your individual requirements, our modular tube bending solutions allow fast cycle times without compromising manufacturing quality. We offer different approaches to suit every requirement. In addition to our fully automated bending cells, we supply a wide range of single-stack and multi-stack machines and machines with two bending heads for especially complex tube geometries.

Please feel free to contact us for advice about the right machine for your needs.

The world’s leading expert in tube bending machines

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.