New Team and Innovative Tube Bending Solutions

Schwarze-Robitec at the FABTECH 2015

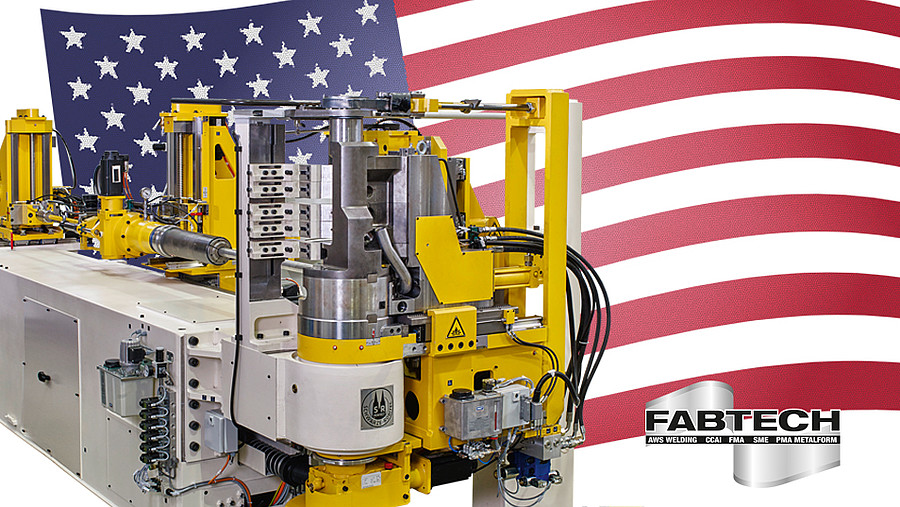

Customer focus, increased customer benefits: The tube bending machine manufacturer Schwarze-Robitec offers its visitors at the FABTECH 2015 in Chicago additional benefits. Between November 9-12, the visitors will meet the complete team of the new US subsidiary at booth #N8103. The tube bending experts have brought along many new products and developments for resource-efficient production processes.

Schwarze-Robitec is the world’s leading manufacturer of Tube Cold Bending Machines. The long-standing German company, founded in 1903, develops and manufactures tube bending machines for the automotive, shipbuilding and offshore industry, power plant construction and the chemical industry as well as special bending solutions for many other branches of industry. To improve the service for the continuously rising number of customers from North America and Mexico, Schwarze-Robitec has now opened its own US subsidiary in Michigan. Chris Dorgan, President of Schwarze-Robitec America Inc. and his team, together with the experts from Germany will present the entire product line at the Fabtech. The range of products includes tube cold bending machines, bending tools and application-specific equipment. Regular customers and new customers from the USA, Canada and Mexico benefit from the customer-specific on-site advice, shorter delivery times for spare parts and attractive conditions.

Trade show highlights

The company will present its entire modular, configurable high-performance machines with newly developed CNC control system and innovative accessories at booth #N8103. The state-of-the-art solutions demonstrate how companies in the automotive industry can supply today’s high-performance series production of tube systems ever faster and more cost effective. The new addition to the bending machine expert’s accessory is the innovative cutting tool. It reduces the tube waste by up to 90% and shortens the production times considerably. While the previous process required the use of an external shear in order to separate the component from the tensioning or support device after the bending process, this new tool requires only one work step to complete the bending and separation process. The rapid clamping system “Quick Tool Unlock” provides another “time-saving” potential. The central tensioner makes changing bending equipment fast and without the use of any additional tools. If different radii are required, bend-in-bend systems or tube systems (manifolds and exhaust pipes) must be produced, Schwarze-Robitec recommends tool bending machines with multi-radius bending tools that can be adjusted individually. One more highlight at the trade show is the new CNC machine control system. During the execution of the current process, this control system prepares already the subsequent work step. The operation of the system is intuitive and the relaunch of the state-of-the-art design contributes to an ergonomic and efficient procedure.

Schwarze-Robitec America Inc.

Schwarze-Robitec America Inc. sells Tube Cold Bending Machines ranging from 1/8” to 16” as well as bending tools and application-specific machine equipment. In addition to this, the team of experts implements spare parts procurement, machine maintenance as well as inspections and advises users with regard to modifications, major overhauls of existing machines and optimization of bending processes. Worldwide, Schwarze-Robitec GmbH has already sold more than 2,400 machines, many of them have been in unrestricted production runs for more than 35 years.

The contact data for the US subsidiary are as follows:

Schwarze-Robitec America Inc.

Phone +1-231-598-9125

Fax +1-231-598-9097

E-Mail: us-sales@schwarze-robitec.com

E-Mail: us-service@schwarze-robitec.com