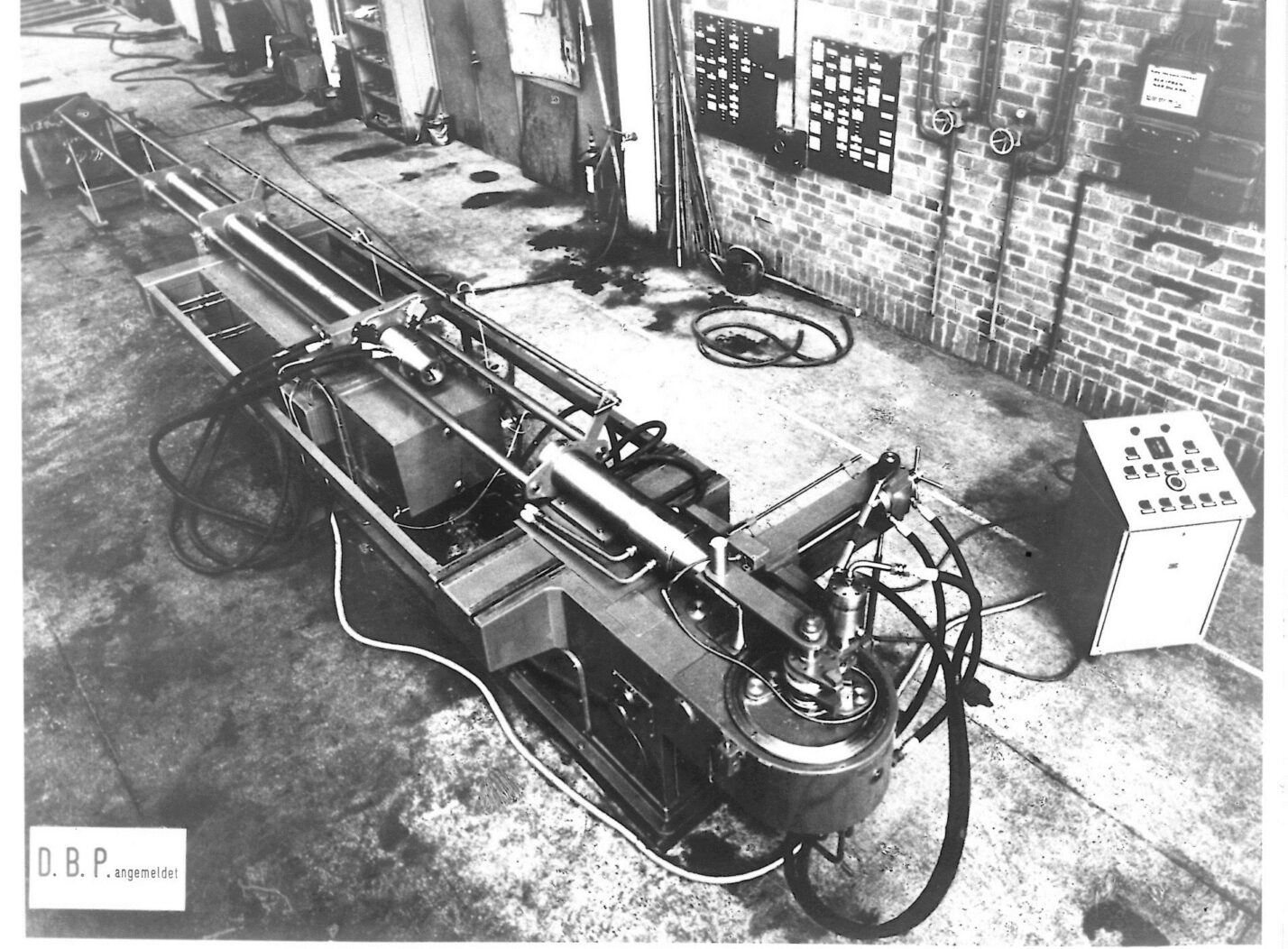

Tube bending machine for small diameters

Order from China: Schwarze-Robitec develops a compact CNC 25 E TB MR

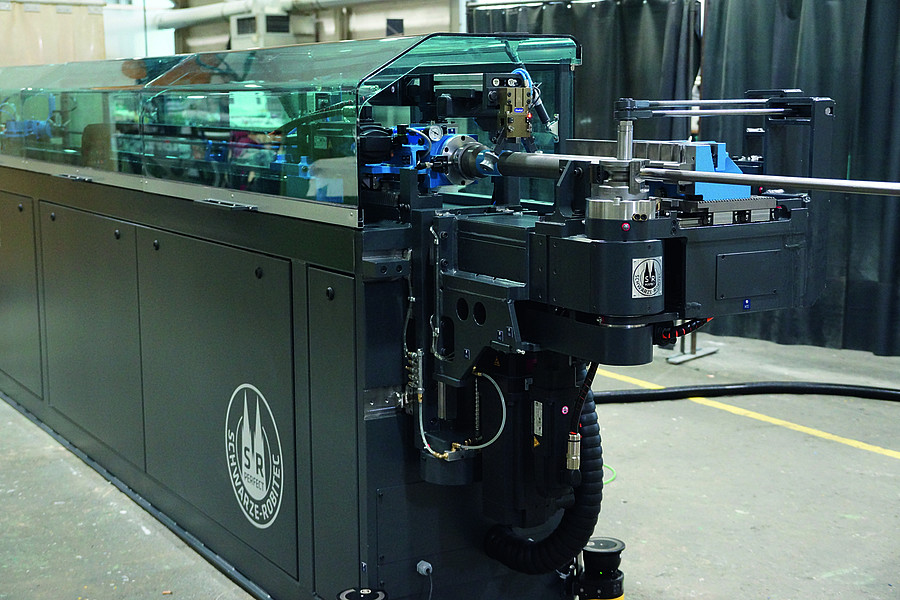

With the new fully electric CNC 25 E TB MR Schwarze-Robitec delivered a high-quality, compact tube bending machine sporting the “made in Germany” seal to China. The Cologne-based tube bending specialist thus fulfils its client’s requirement for outstanding quality, high production speed and machine availability. For the first time, Changzhou Liangxu Vehicle Accessories Co., Ltd., is now able to bend smaller tube diameters extremely fast and as part of a fully electric process – thanks to the NxG control system.

Chinese automotive industry supplier Changzhou Liangxu Vehicle Accessories Co., Ltd. manufactures injection tubes and radiator outlet pipes for cars and trucks and is the main supplier of tube systems for China’s third-biggest truck manufacturer. At the company’s headquarters in Changzhou on the Yangtze River in eastern China, Schwarze-Robitec recently put a new CNC 25 E TB MR into operation. The delivered machine version is capable of bending steel tubes with a diameter of up to ca. 1 inch and a wall thickness of ca. 0.08 inch as well as stainless steel tubes with a diameter of up to ca. 0.8 inch and a wall thickness of ca. 0.06 inch.

This means that, for smaller tube diameters, Changzhou Liangxu Vehicle Accessories Co., Ltd., is using a fully electric machine with NxG control for the first time. It offers major benefits: depending on the tube system, the NxG control system enables up to 50 percent more output thanks to the simultaneous operation of the axes. The company is thus ideally preparing itself for the rise in demand brought on by the prolonged boom in China’s automotive industry.

Space-saving machine design

With the CNC 25 E TB MR, Schwarze-Robitec has developed a new machine size for small tubes. It is available in both left/right bending versions as well as in a rotary variant, with the bending head capable of rotating 180 degrees. Tubes with complex geometries can thus be bent in one process step. The machine also features a space-saving design and state-of-the-art safety technology. Thanks to intelligent scanners and a slim machine bonnet, the machine can be operated without any additional safety fences, allowing for the available space to be optimally used. As the electrical technology is integrated into the machine body, the machine requires no additional control cabinet and can therefore be easily moved around the production area if necessary. In addition, the CNC 25 E TB MR is equipped with a freely stored bend former: The bending table and bend former can be operated independently of each other – a particular highlight of all of Schwarze-Robitec’s machines. This feature gives the user much more freedom when bending tubes and thus simplifies the entire bending process.

In Changzhou, the new CNC 25 E TB MR impressed the client with its extremely high production speed thanks to NxG control. Therefore, while delivering the new product to Changzhou, Schwarze-Robitec also modified two additional machines and integrated the latest control system.