Efficient tube bending process thanks to Schwarze-Robitec

New circular cutting device: cutting tubes without material waste

When it comes to bending tubes, each step of the process that can be removed helps to increase efficiency. That’s why the German tube bending machine manufacturer Schwarze-Robitec is now offering a new machine feature. Just like the fully electric cutting tool, the new circular cutting device is also able to combine the two process steps of bending and cutting. With outstanding cutting quality, it cuts tubes without creating shavings and helps to further reduce material waste.

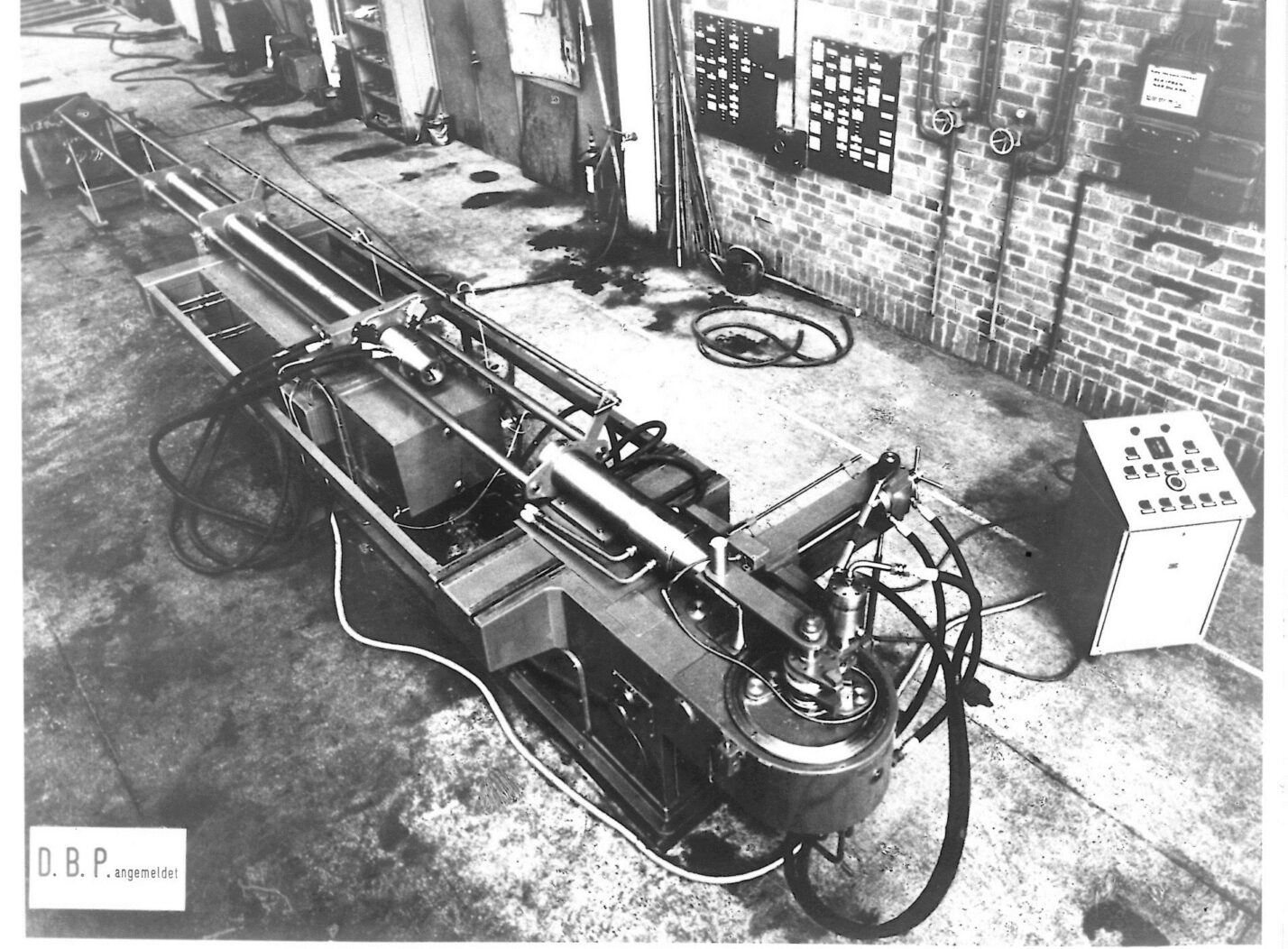

When series-produced tubes are bent, they typically need to be cut in individual pieces. This process step hampers the efficiency of the overall tube bending process. Schwarze-Robitec therefore uses various machine features to tackle this issue. The Cologne-based company’s latest feature is the circular cutting device, which it has incorporated into the fully electric multi-radius tube bending machine CNC 80 E TB MR. It is ideally suited for mass producing bent tube systems made from various materials. The simultaneous operation of all machine axles thanks to NxG control provides the user with extremely short turnover times. Moreover, a freely stored bend former offers a large degree of freedom while bending. The CNC 80 E TB MR thus enables a highly efficient tube bending process in demanding industries such as vehicle production.

Near-perfect cutting quality without additional calibration

Whilst Schwarze-Robitec’s electric cutter cuts through tubes with a blade, the new circular cutting device uses a different method: Positioned 120° apart, three cutting wheels circle around the tube several times, gradually cutting through the tube. The wheels consistently cut away at the exterior surface of the material and a small ridge forms on the edge of the tube. No shavings are produced in the cutting process that would otherwise have to be additionally removed. The circular cutting device is therefore particularly suited to users who require near-perfect cutting quality and who want to eliminate the need for any additional calibration. In contrast to cutting with a blade, the tube edge does not need to be subsequently moved on to a mandrel for processing.

Schwarze-Robitec has further developed the tried-and-tested cutting method for the tube bending process, ensuring it meets practical requirements. The circular cutting device is integrated into the machine in such a way that the cutting point can also be between two bends. Intermediate lengths can thus be reduced to a minimum, fulfilling the demand to continuously reduce material waste. This new combination of bending machine and circular cutting device ensures that the tube can be ideally positioned to fit the cutting head and vice versa. This gives users a high level of flexibility when designing tube systems. The circular cutting device’s wear parts are conventional standard cutting wheels, which can be easily replaced after being worn down.

Electric cutting tool or circular cutting device? Schwarze-Robitec offers tube bending machines with these two fundamentally different cutting methods. They each have their own advantages. Schwarze-Robitec provides users with individual advice to help them find the right solution.